To celebrate a partnership with a well-known German tool brand

Makita from Facebook.

We offer 30 highly subsidized campaigns

The duration of the event is limited, don't miss it!

Only for FB users!

The duration of the event is limited, don't miss it!

Click to order from the link on fb and we also offer a free 2-year warranty!

For Facebook users only!

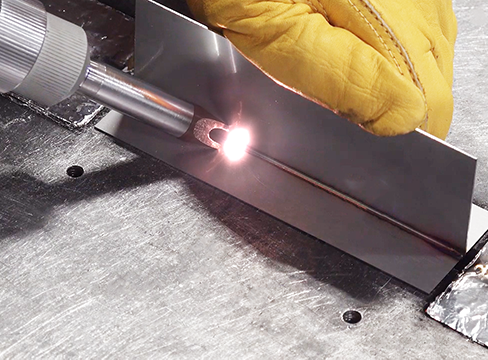

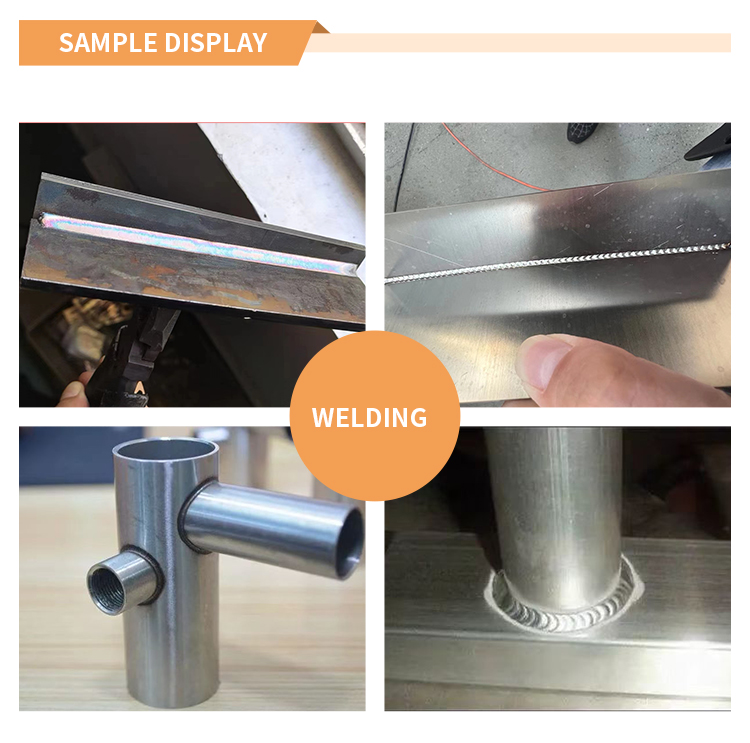

Don't have a professional welder?

It's nothing

Even beginners with no welding experience can make perfect welds with our laser welding guns.

Usually, only one day of learning is enough to achieve qualified welding results.

Why laser welding?

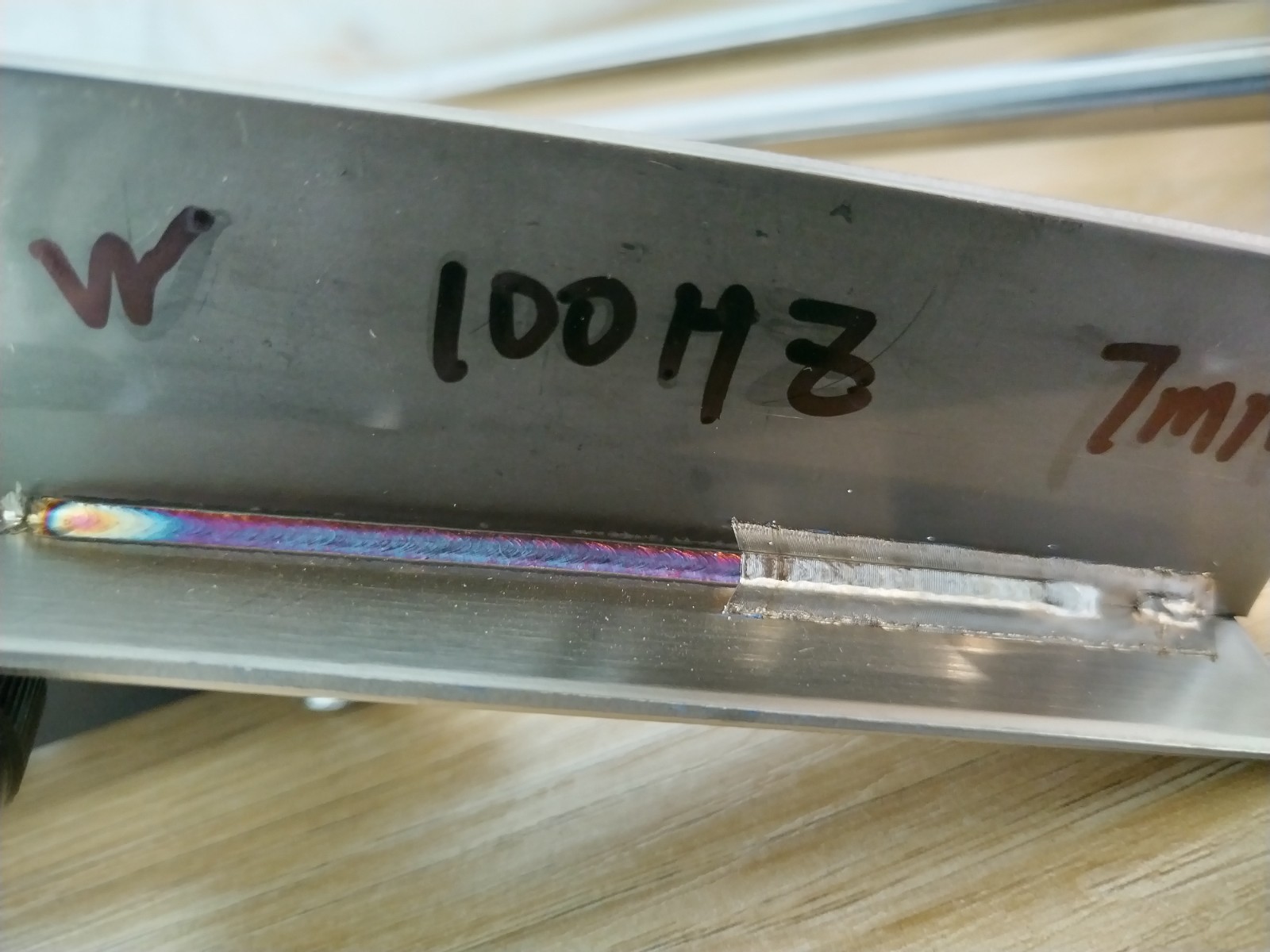

7KW prodire do 10-30 mm.

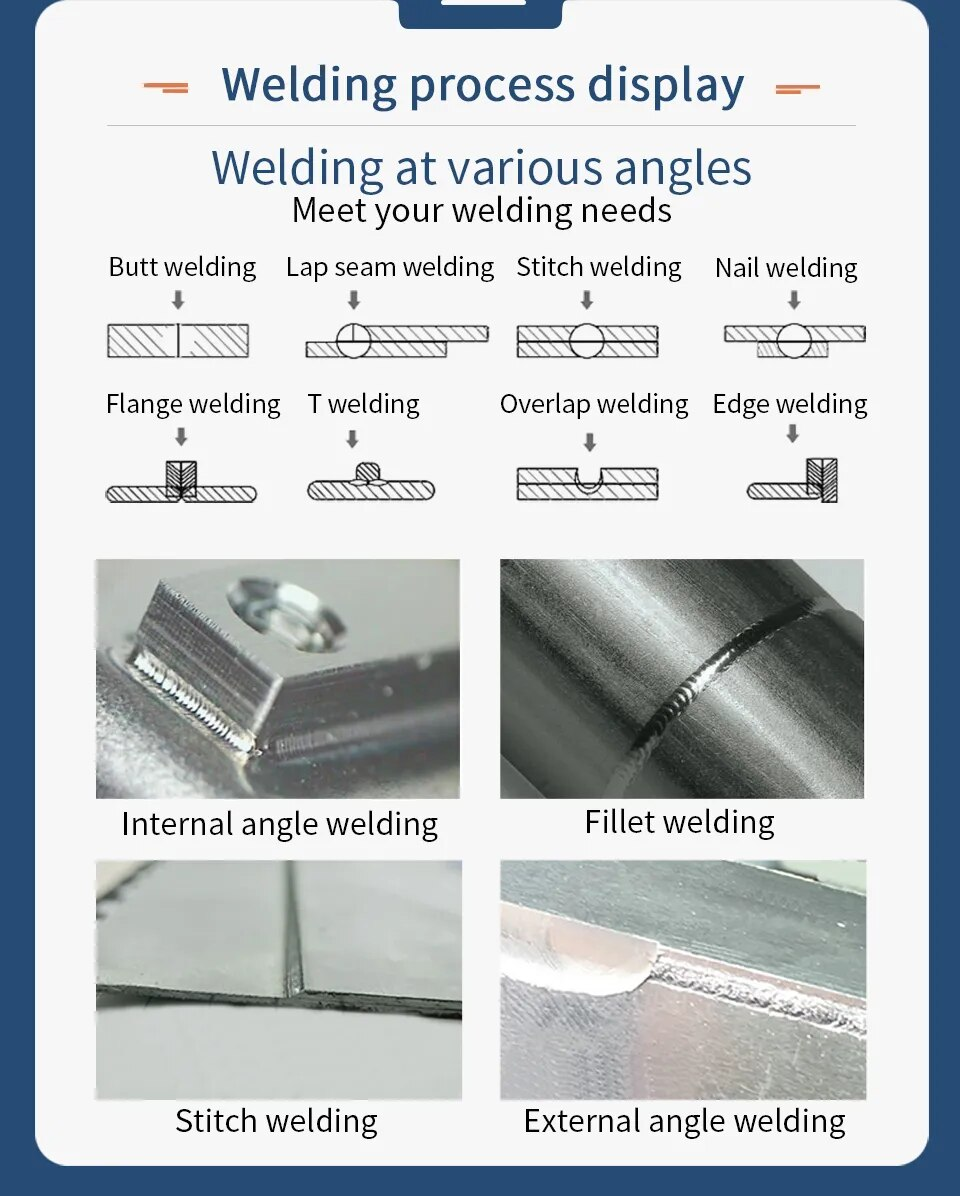

Good results without adding wire

It is easier to achieve good results even without a certified welder.

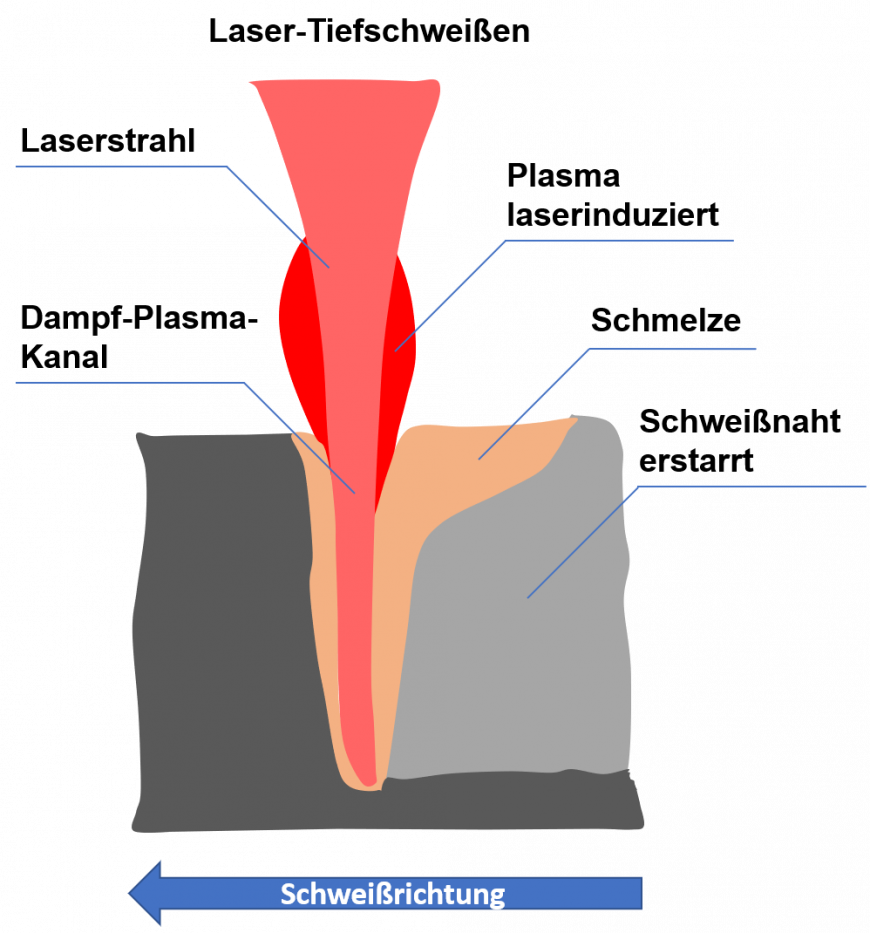

The working principle of laser welding

Laser beam welding works by absorbing and transferring heat energy to the workpiece.

Thanks to the very high intensity of our 7000 W laser, the joining area of the workpiece reaches vaporization temperature which leads to a deep welding process.![]()

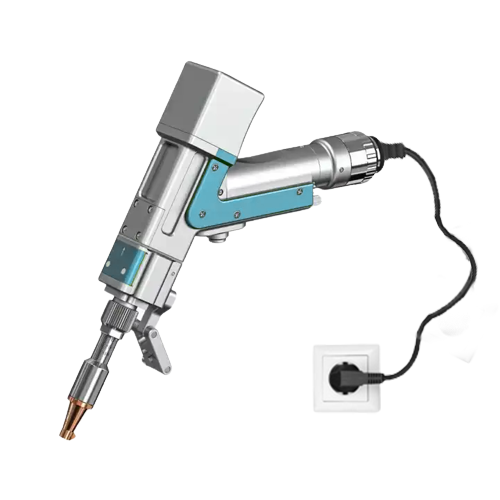

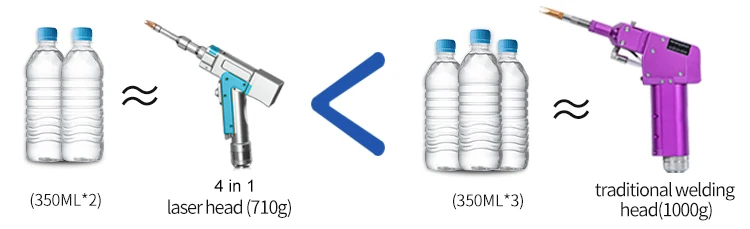

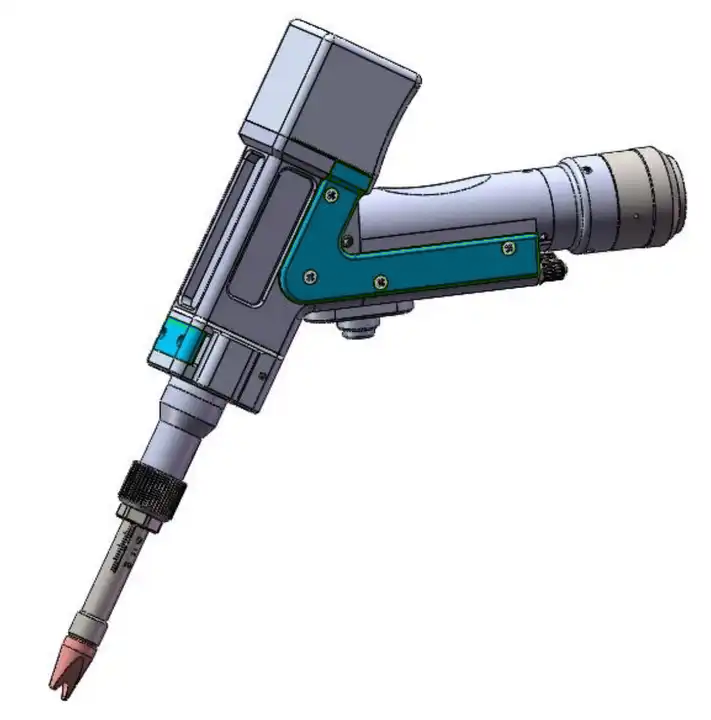

Makita 4 in 1 innovative portable laser gun

It can perform laser welding, cutting, welding cleaning and pickling at the same time.

Power up to 7000W

You don't need to buy other equipment for these different jobs, just one of Makita's innovative 4-in-1 laser welding guns is enough to weld, clean and cut at the same time.

![]()

Look at this

Our laser welding speed

Higher speeds mean more efficient welding and lower labor costs!

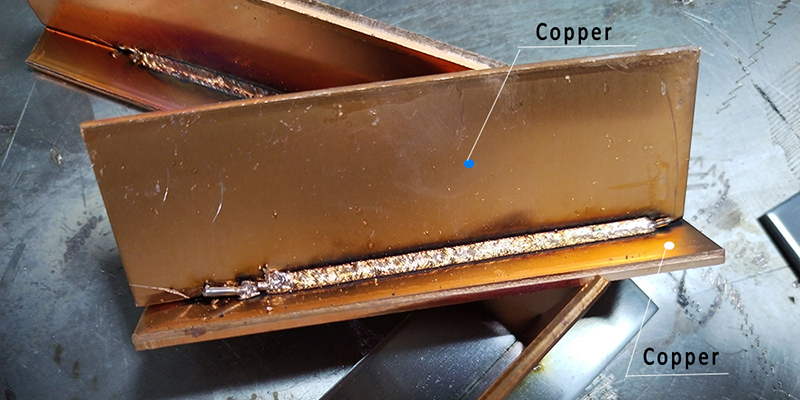

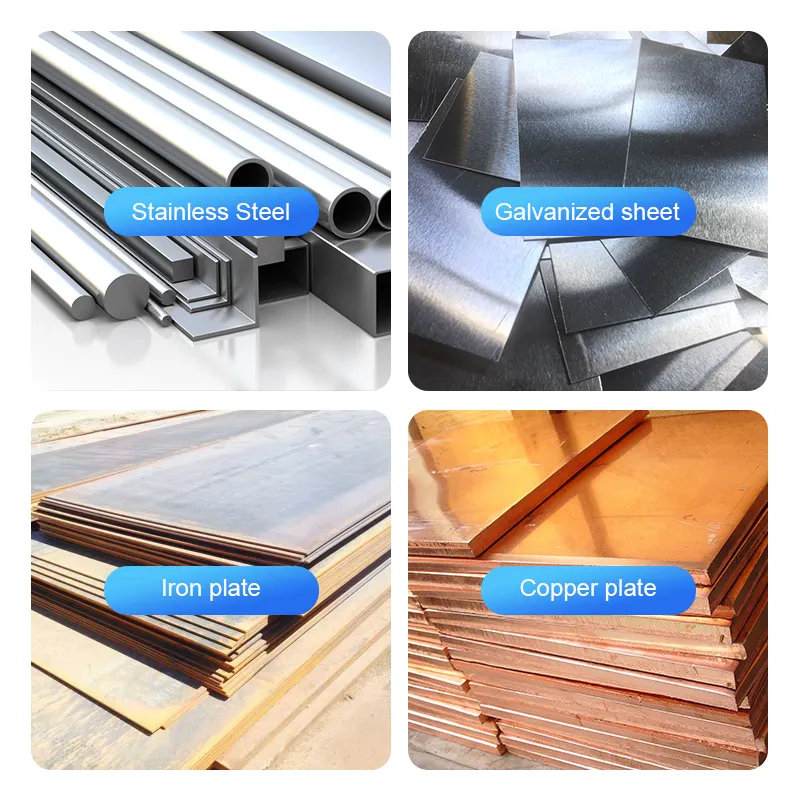

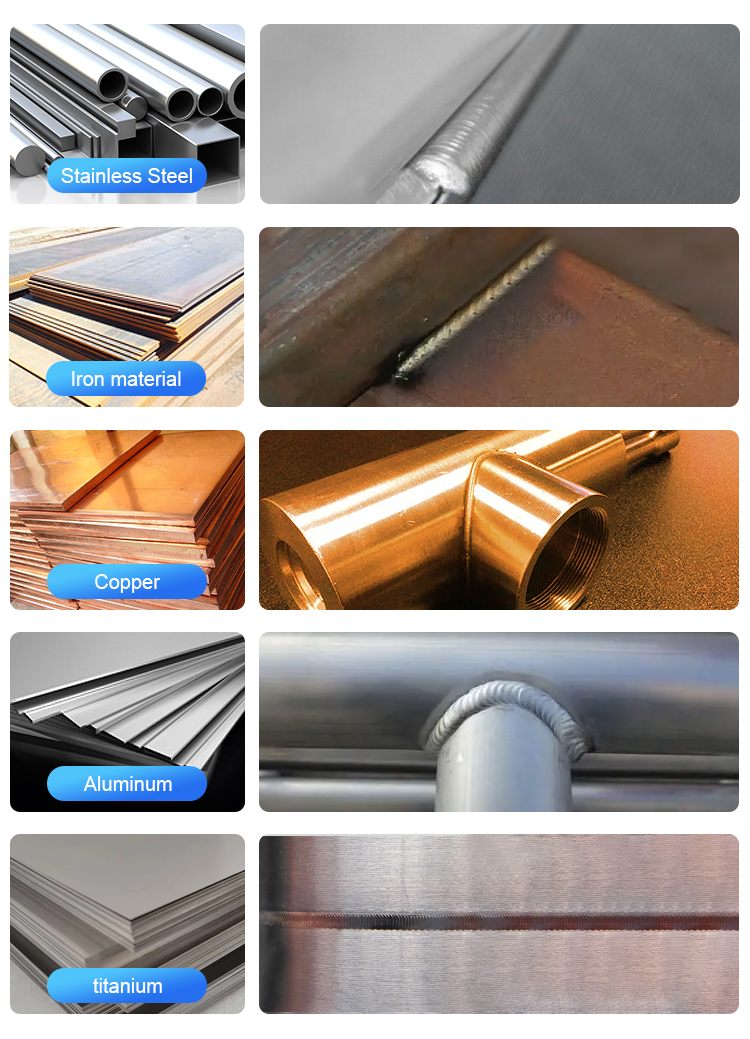

In the past, laser welding machines were widely used for welding stainless steel, carbon steel and aluminum alloys.

Now, copper welding will be a new application of the laser welding machine, which allows you to weld together even different materials, such as welding copper and stainless steel. We have also achieved good welding performance for different materials.

Weld cleaning before or after welding is a common application to improve weld performance and surface quality.

Gap cleaning width up to 80 mm, weld cleaning width up to 10 mm

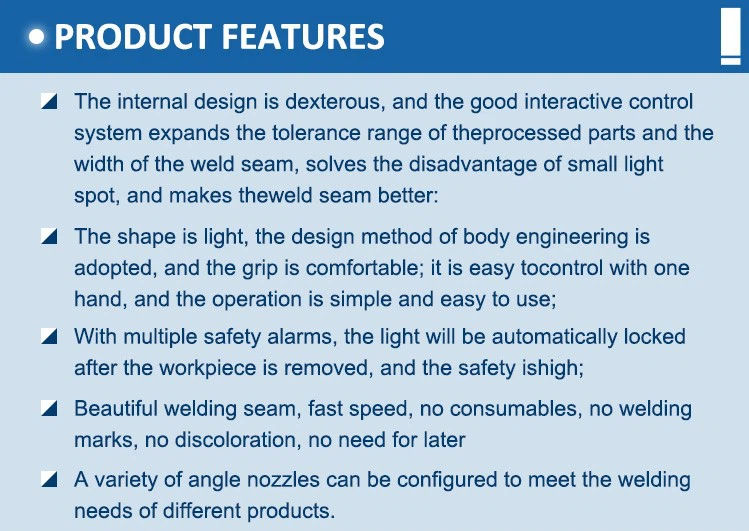

ADVANTAGES OF PORTABLE LASER WELDING MACHINE

1. Outdoor welding is possible.

2. High welding speed, 2~10 times faster than traditional welding.

3. Smooth and beautiful welding seam, large depth, small taper, no grinding required, saving time.

4. There are no deformations or traces of welding, the piece is firmly welded.

5. Compared with contact welding, laser welding does not require electrodes, reduces daily maintenance costs and greatly improves work efficiency.

6. Welding thin stainless steel sheets, iron sheets, aluminum sheets and other metal materials can be a perfect alternative to traditional argon welding and electric welding technology.

Makita 4 in 1 Innovative portable laser gun

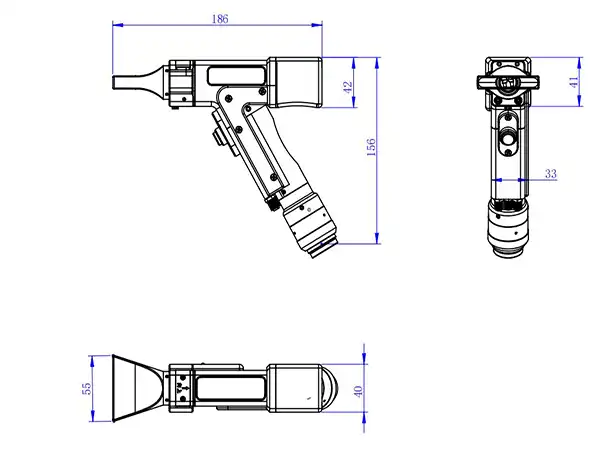

Small size, easy to carry, suitable for everyday work

Manual welding, flexible and practical, longer welding distance

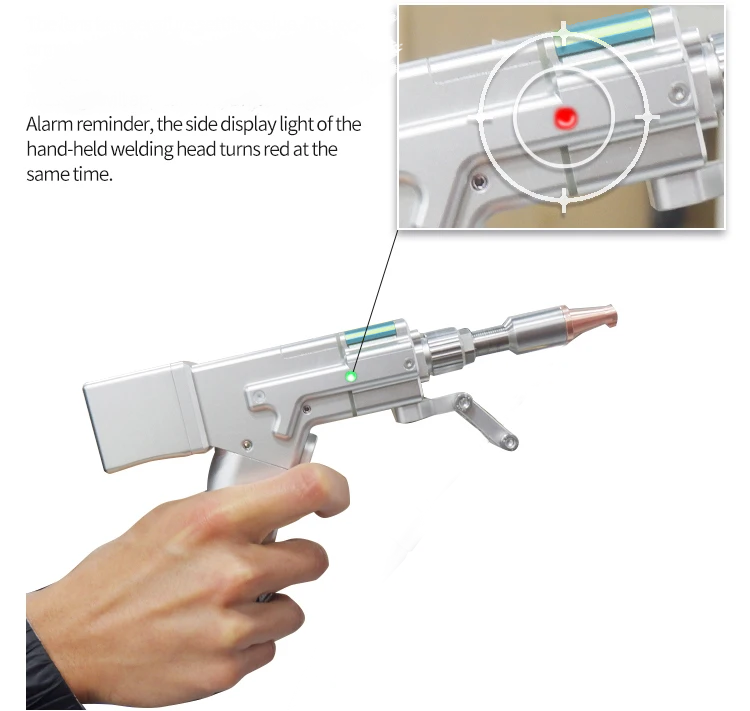

Adapting to different welding requirements, setting multiple safety alarms and status indicators, immediate response to abnormal conditions

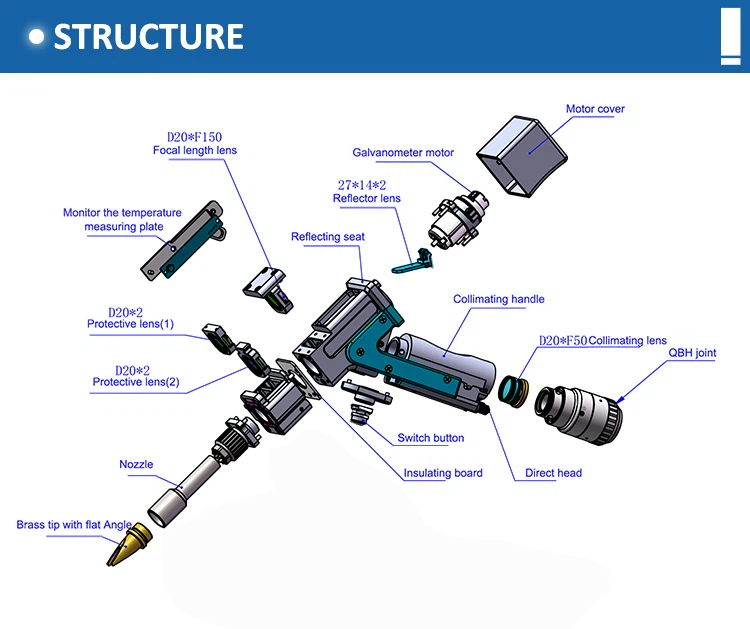

The design of the lamp body and the design of the inserted protective lens

When welding or laser cutting, especially on highly reflective materials such as aluminum alloys or carbon steel, more spatter occurs.

Operators easily change the inserted protective lenses for routine maintenance as well, maximizing the protection of the internal mirrors against focusing, reflection and collimation.

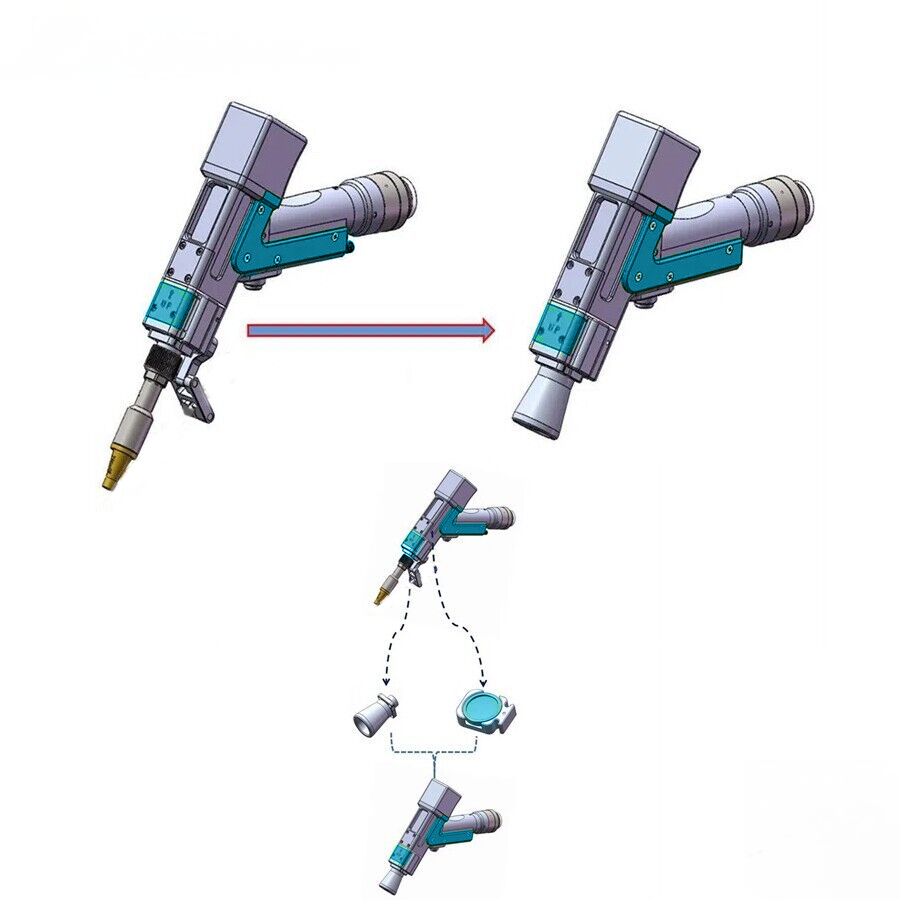

To switch from laser welding to laser cutting, simply replace the welding nozzle with a cutting nozzle.

If you need to switch from laser welding/cutting to laser cleaning, simply change the focusing mirror inserter and cleaning nozzle to go straight to metal stripping.

Cutting stainless steel is easy, you can cut straight or curved lines, or any other shape you want, you can also cut 0-30mm steel.

Laser welding nozzles include normal welding nozzles and feed welding nozzles.

The advantage of the nozzles we use is that they produce less spray than traditional nozzles.

Nozzles are available in brass and copper, depending on the material, and copper nozzles have better heat dissipation than brass ones.

Furthermore, it has the most reliable safety certificate in the world.

It has a stable and high power of 7000W and welds at a speed of 30m/min,

welds stainless steel, steel, aluminum alloys and more...

Portable laser welding technology uses a laser beam as an energy source to strike the weld and create the weld.

It not only solves the problem of traditional welding, but also increases waterproofness when working under water and on rainy days (completely avoiding the problem of not being able to work on rainy days and greatly improving work efficiency).

*According to logistics requirements, it is necessary to specify the house number when entering the address, otherwise the order will be automatically canceled, thank you for your cooperation.

I will never forget 30 examples ←

【Limit to 1 person】 Please note that you will receive duplicate rings, so the best part of the ring will be yours.

Poznámka pro uživatele